Cloudy beer seems to have become vogue these days, what with the giant IPAs that look like orange juice. Don’t get me wrong, I’ve stood in line for hours myself to buy some pretty insanely priced, and insanely delicious, beers of this type. At the risk of alienating some of my good and supremely generous beer friends, this new fad in beer isn’t something I aspire to recreate in my own brewing.

To filter or not to filter

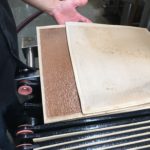

New filter media

We’ve heard arguments supporting both sides of filtering. Pro-filter brewers view filtering as the hallmark of good craftsmanship and think it proves they care about what they sell to customers. Anti-filter brewers insist that filtering can remove flavor and aroma components. I argue that both sides of this debate have merit and that a middle ground exists for homebrewers and professional brewers alike.

Filtering in the garage

Those of us who homebrew can either “filter” with fining agents, such as gelatin, or by conditioning the beer longer, allowing it to clear naturally through temperature and good old gravity. It’s not like I have a filter setup, so I let my beer sit in secondary fermentation for 1-4 weeks and am rewarded with a reasonably clear beer that gets transferred to the keg. If I then cold condition the beer at 33-35°F for another couple of weeks, the beer clears even further. Neither of these approaches are financially viable for the pro brewers in a world where time = money.

Inserting the media

Filtering

What it removes

The pros have two choices. Filter or Don’t. Some beers are a no-brainer. Hefeweizen, Wits, wheat beers, saisons, etc. are all cloudy by nature, so filtering isn’t necessary and may in fact change the character of the beer. Lagers, IPAs, pale ales and other ale styles can definitely benefit from filtering. But some drawbacks and other matters have to be taken into consideration when filtering. The filter medium can obviously take out things like yeast, remaining trub and even the proteins that form chill haze. Those are all good things to remove, but you can also remove flavor and aroma character.

So if you want to filter your IPA that all your friends rave about, how could you do it without losing that hop character everyone loves so much? I listened to homebrew royalty talk about filtering recently, and he answered the dilemma of removing hop character with three simple words. “Add more hops.” Brew your IPA, filter it and compare to the original non-filtered version, then adjust your recipe.

Filtering beyond the garage set-up

Outside of the garage, filtering is a little more precise. In my internship at a small brew pub, I recently got the chance to participate in the filtering of three different beers in the same day. The machine is basically a series of plates where the beer flows through an orifice on one plate, through the filter media, and then out another orifice on the next plate. The plates alternate back and forth and the beer is moving through more than 20 of the plates on this particular filter.

Once the brewers have inserted the filtering media between the plates of the filter machine, they compress the plates until they are just barely touching each other. Then, they spray the filtering plates and media with fresh water to allow for expansion, and pump cold fresh water through the filter to facilitate even more expansion. The filter is compressed again to slow the leaking between the plates. This hydrate-compress process is repeated until the filter is completely hydrated and the leak rate is minimal. Finally, before the beer goes through, the filter is sanitized with sanitizer or boiling water. On this particular day, I watched more than 100 gallons of boiling water go through the filter to sanitize it. As a side note, wearing gloves while handling the hoses after 100 gallons of boiling water have gone through the filter is highly recommended. At last, using CO2 pressure, we pushed beer through a pump, through the filter, and into the brite tank.

The pump is in the line to help push the beer through the filter because the fermenter is only rated to 15psi working pressure. As the beer starts flowing through the filter media, and the media strips out impurities, the flow of beer out of the filter slows. This is where the pump becomes critical. Once the fermenter is completely empty, we remove and replace the filter media. It is possible to use the filter media a second time if the filter is back-flushed and sanitized a second time.

The reward for filtering is immediately apparent. I watched hazy beer in the sight glass of the “in” side, and clear beer fill the “out” sight glass. I would also be an idiot if I did not mention the beer in the fermenter is already cold (33°F). This is done because any proteins that would form a chill haze will be present and are then filtered out. A well-known brewery that touts its cold-filtered system sounds impressive, when in fact, cold-filtering is the industry standard for breweries that produce 200 barrels a year and those that produce 50 million barrels.

My take

The concept of filtering is a tough one for me personally. I have always taken time to ensure that my beers are as clear as possible before serving or entry into competition. The key point is that this takes time. The “shortcut,” if that’s even the right term, is to actually filter the beer. I guess ultimately this is a matter of personal taste, style and economics. Filtering systems aren’t cheap, and the process isn’t as easy as you would think. Filtering takes time and is incredibly boring. Trust me, I spent eight hours filtering. The payoff is holding a beer up to the light and seeing crystal clear beer.

Much to my wife’s dismay, I see a filtering system being added to my inventory.

At this point in the homebrew infatuation, who hasn’t thought of quitting their day job and going pro? After five or more beers, just about every serious beer drinker (let alone brewer) with whom I’ve ever had a conversation mutters something along the lines of: “Wouldn’t it be effing cool to own your own brewery?” Well, I’ve asked myself, and my adorable wife, that question many, many times.

At this point in the homebrew infatuation, who hasn’t thought of quitting their day job and going pro? After five or more beers, just about every serious beer drinker (let alone brewer) with whom I’ve ever had a conversation mutters something along the lines of: “Wouldn’t it be effing cool to own your own brewery?” Well, I’ve asked myself, and my adorable wife, that question many, many times.